Product Description

Usage:

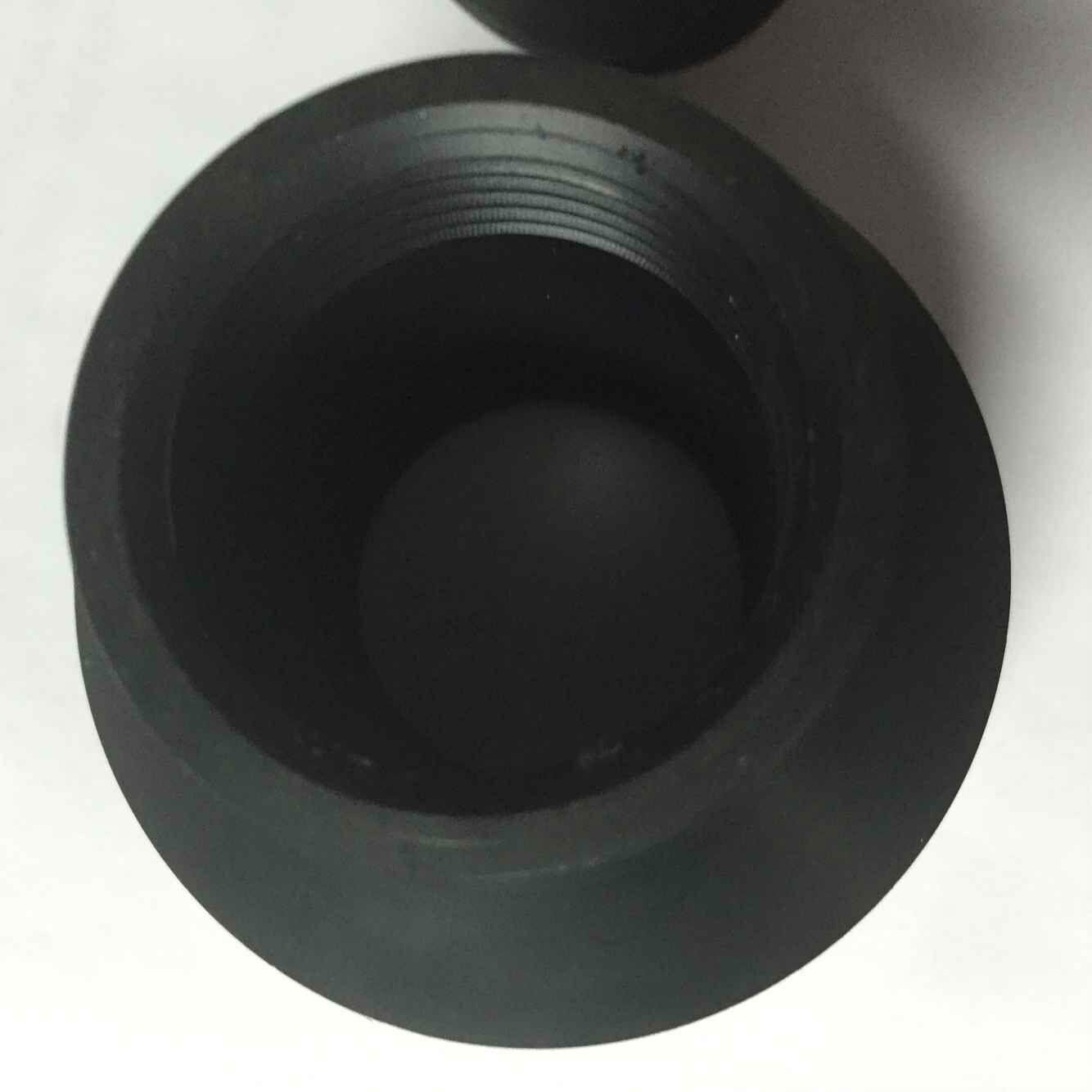

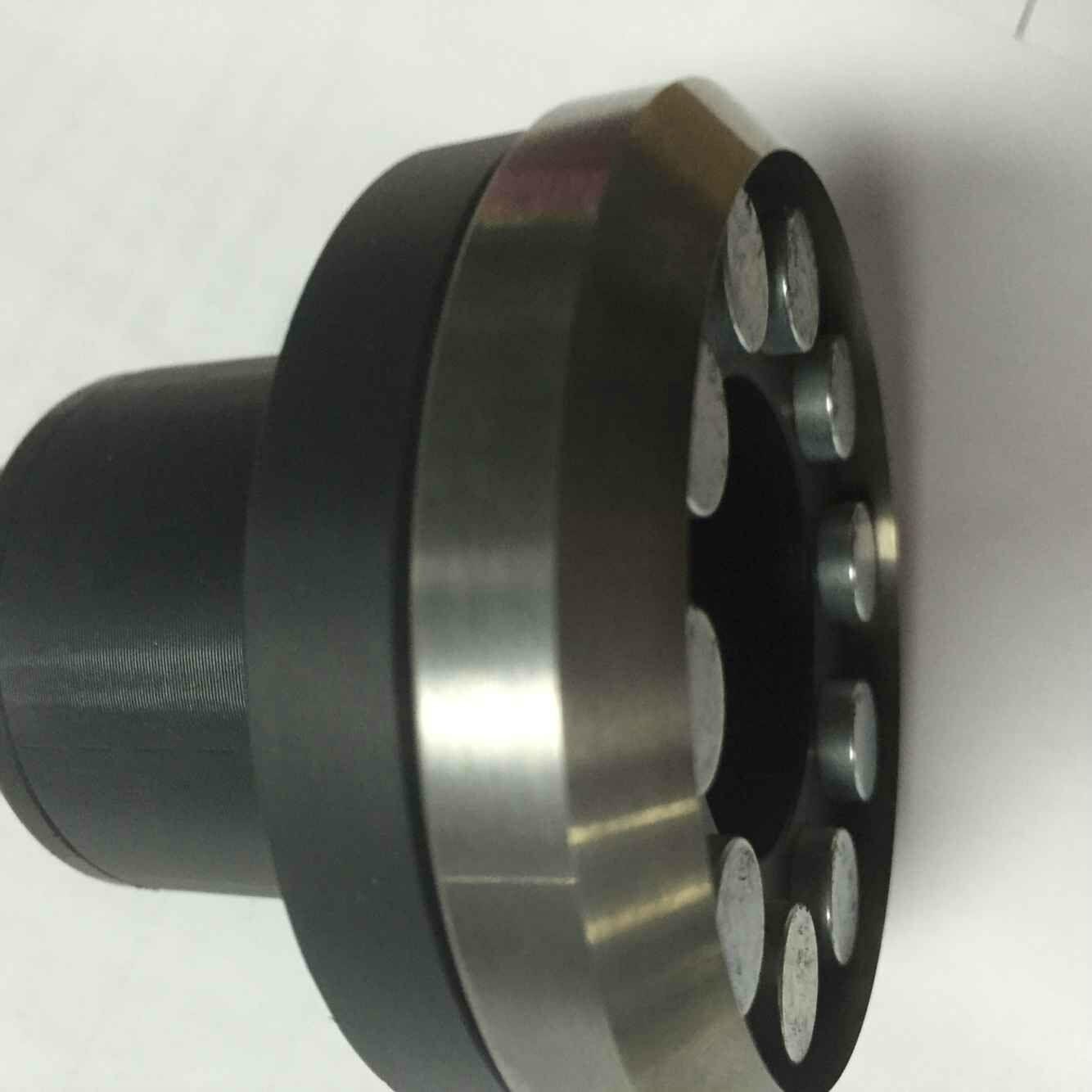

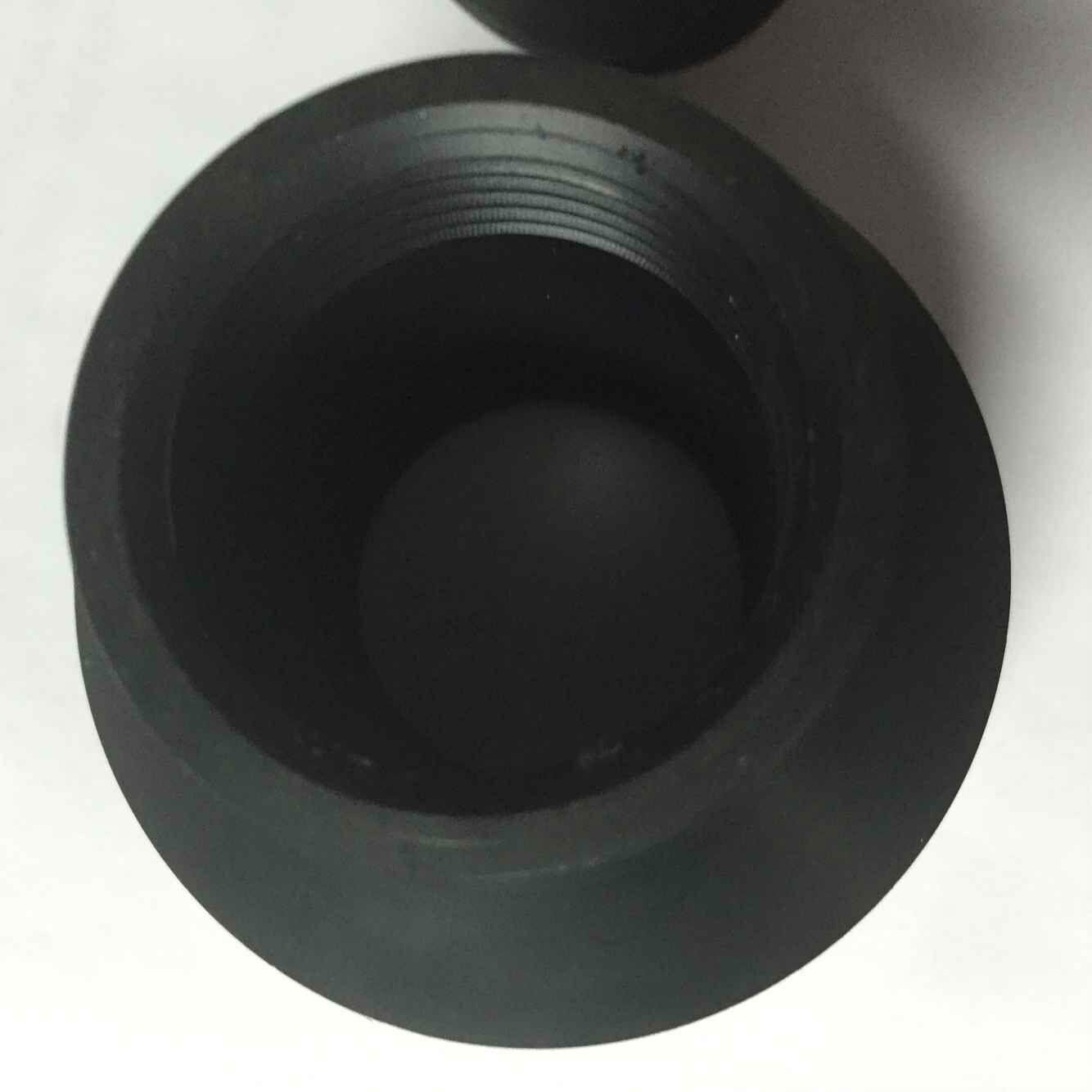

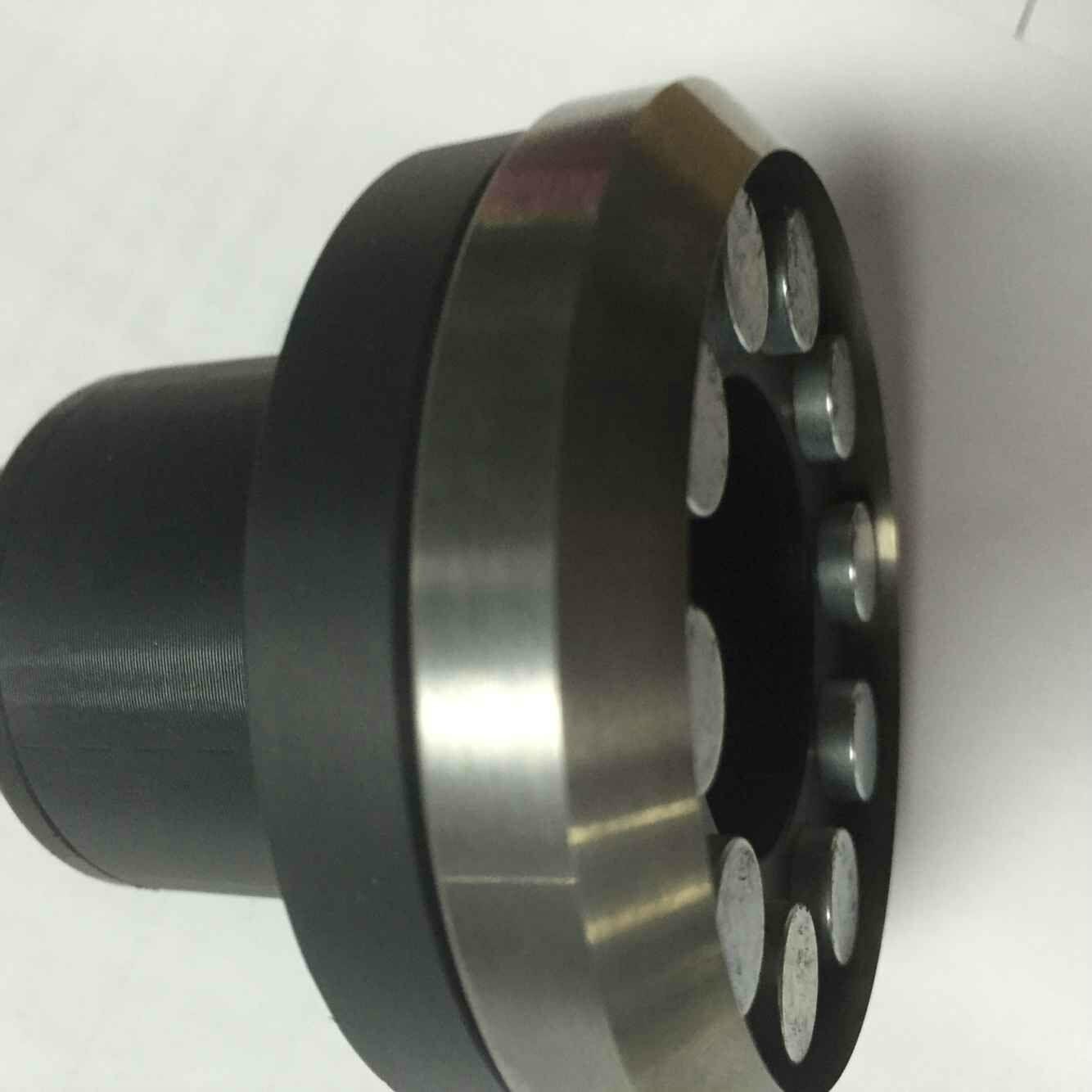

Installed on the sealed cup pad printer to store ink and thinner; Meantime, Both Covering ink and removing ink function same as Steel blade. Sealed cup is consist of two parts: the Ink Cup ring and body part , The ring part of the installation in the cup body, wear occurs when the ring can be replaced. Now the knife ring are made of common two materials: ceramic and tungsten steel.

Technical Parameter:

60mm diameter:

- Point Angle: 60 Degree;

- Hardness: 62 Degree;

- Material: Tungsten Steel;Ceramic

- Diameter of Inner loop: 60mm.

90mm diameter:

- Point Angle: 60 Degree;

- Hardness: 62 Degree;

- Material: Tungsten Steel;Ceramic

- Diameter of Inner loop: 90mm.

140mm diameter:

- Point Angle: 55 Degree;

- Hardness: 63 Degree;

- Material: Tungsten Steel; Ceramic

- Diameter of Inner loop: 140mm.

Production Advantage :

- Well abrasive Resistance, long useful time;

-

- Sophisticated cutting edge, compact with Steel plate;

- Idiosyncracy angle of cutting edge, fit storing and coating ink;

- With mouth on the top, easily change and add ink and thiner;

- Magnet Decentrality distribute, removing ink easily but light press;

- Change Ceramic ring to match Resin plate;

- Ink can be cleaned easily.

Use Method:

- Taking of steel plate from sealed cup pad printer;

- Cover the sealed cup on steel plate slowly, then move it to the center of steel plate;

- Install steel plate coverred with sealed cup on pad printer;

- Fix the steel plate, Fix sealed cup to the cup frame;

- Adding ink and thiner into sealed cup, push the sealed cup and examine ink;

- Increase the pressure ensure removing ink completely.

Caution:

There is sharp cutting edge which has high brittleness, Please aviod Collision and dropping; Because of Magnetism, When closing to steel objects, Please controlling speed.

Storage:

Store in Pliable case made by Foam. Avioding contact with steel materials.

Price Terms︰

EXW,Dongguan,China

Packing︰

Case

Lead Time︰

2 days after confirm payment

Product Image